What's the Functions of Casing Head Assembly in Wellhead Equipment

In the operation of wellhead equipment, casing head assemblies play a critical role in ensuring efficient and safe extraction of oil and natural gas from reservoirs. Understanding how casing head assemblies work is critical for anyone in the oil and gas industry. In this blog, we’ll take a closer look at the function of the casing head assembly and its significance in wellhead equipment.

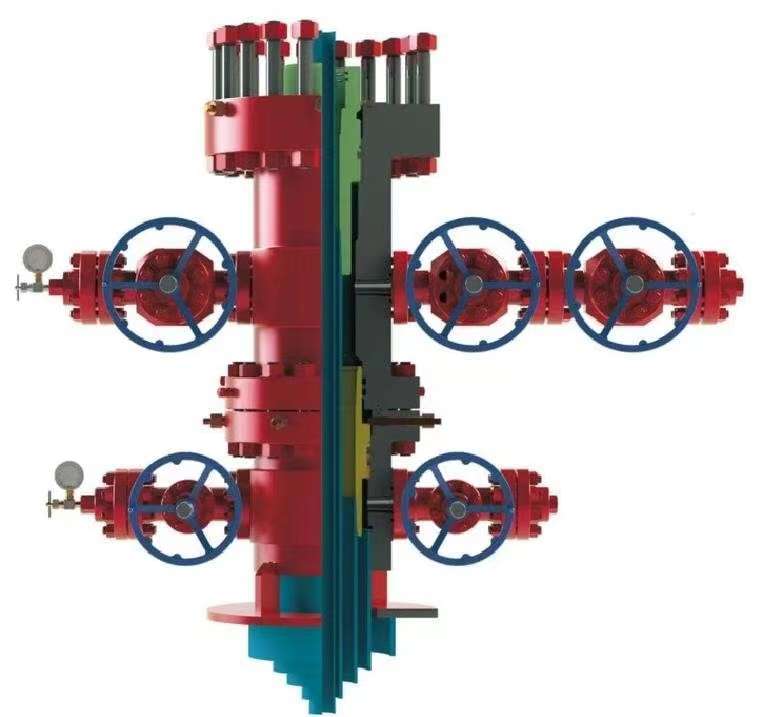

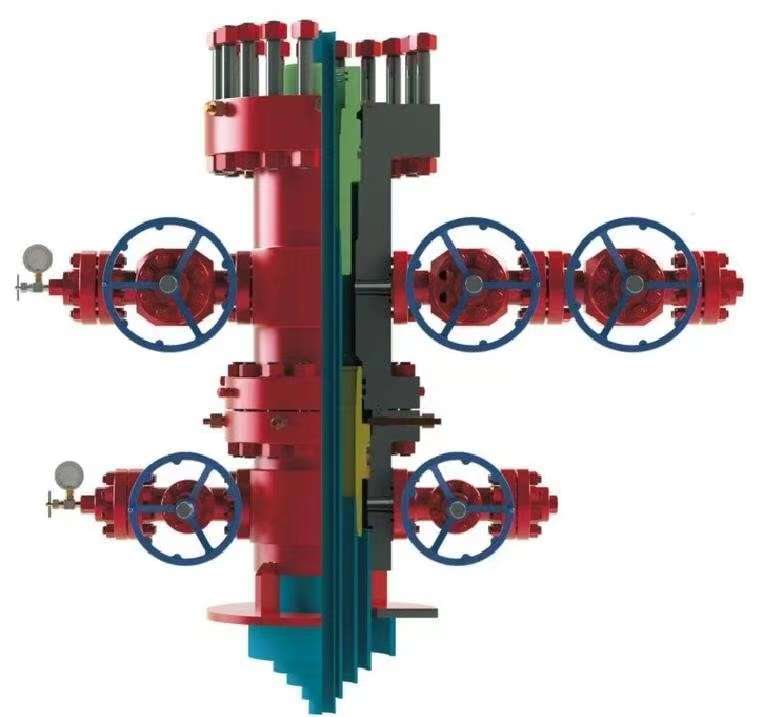

The casing head assembly is an important part of the wellhead equipment and serves as the interface between the surface casing and the blowout preventer (BOP) stack. Its main function is to provide support for the weight of the casing string and to seal the annular space between the casing and the wellbore. This is critical to maintaining the integrity of the well and preventing any potential leaks or blowouts.

One of the key elements of the casing head assembly is the casing head, which is a large cylindrical component installed at the top of the wellhead. The casing head provides the means for suspending the casing string and also serves as a housing for the casing hanger and seal assembly. The casing hanger is a critical part of the assembly because it supports the weight of the casing string and provides a seal between the casing and the wellhead.

The casing head assembly also includes a series of casing spools that accommodate the casing hanger and provide a means of connecting the casing head to the blowout preventer stack. These spools are designed to withstand high pressures and provide a secure connection between the casing head and BOP stack, ensuring the integrity of the wellhead equipment.

In addition to providing support for the casing string, the casing head assembly also plays a vital role in the cementing process. After the casing string is lowered into the wellbore, cement is pumped into the casing and circulates upward in the annular space between the casing and the wellbore. The casing head assembly provides a way to divert the flow of cement and ensure it is properly distributed around the casing, creating a strong bond between the casing and the wellbore.

Additionally, casing head assemblies are designed to accommodate a variety of wellhead tools and equipment, such as casing hangers, tubing hangers, and other components necessary for well operation and maintenance. This versatility enables efficient installation and operation of wellhead equipment, making the casing head assembly a critical component throughout the completion process.

In summary, the casing head assembly is an integral part of the wellhead equipment that supports the casing string, provides sealing between the casing and the wellhead, and facilitates the cementing process. Its role in maintaining well integrity and ensuring efficient well operation cannot be overstated. Understanding the function of the casing head assembly is crucial for any player in the oil and gas industry as it is an essential component in extracting oil and gas from the reservoir.