Hot Products

Hot Products

The production system of Mining Industry is a complex system composed of many links.

In coal mine drilling, complicated geological and hydrologic conditions, thick alluvium of topsoil, many quicksand layers, large water inflow, large well diameter, deep wellbore, and often concentrated operation scale, as well as high temperature, high pressure and high formation stress in the deep well, will greatly aggravate the severity of underground complexity and the difficulty of treatment.

Some problems should be solved according to the characteristics of coal mine drilling:

1.The problem of increasing drilling speed.

2.Prevention and treatment of well collapse, diameter reduction, drilling drop and other accidents.

3.Anti-deviation technology.

4.High temperature resistance。

5.Problems of cutting tools in deep well construction.

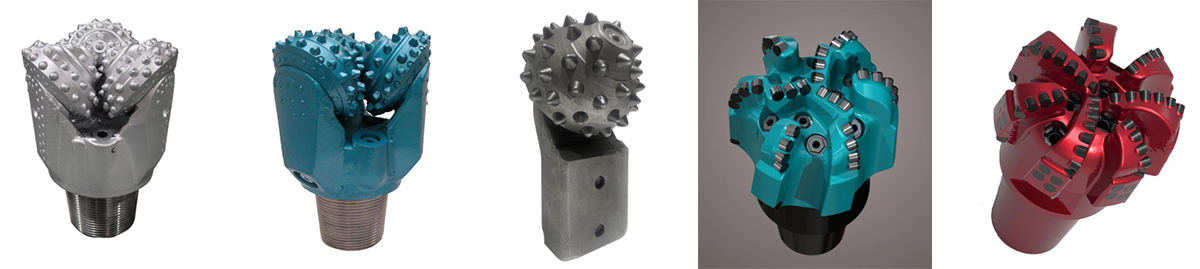

Therefore, it is necessary to perfect the structure of the large-diameter bit.With the increase of drilling fluid density and well depth, the fluid column pressure exerts a pressure holding effect on the broken cuttings at the bottom of the well, and the broken cuttings from the cone bit are not easy to leave the bottom of the well under the action of differential pressure, resulting in the formation of a cushion at the bottom of the well, reducing the crushing efficiency, etc. Reasonable bit structure will speed up the flow of cuttings in the bottom hole, improve the crushing efficiency, accelerate the drilling speed and shorten the drilling cycle.

As well as improving the life of the roller bit, the service life of the roller has a great impact on the construction cost of drilling well. The life of the roller bit mainly depends on the life of seal, bearing and parent.

GRAND Mining tricone bit is utilized for blasting hole open pit mining. Depending on the different formations of customers, we can offer different product , the sizes ranged from 6 3/4" to 16".

Mining tricone bit, we recommend 532、632、642、722 etc..

MOST COMMON PRODUCTS:

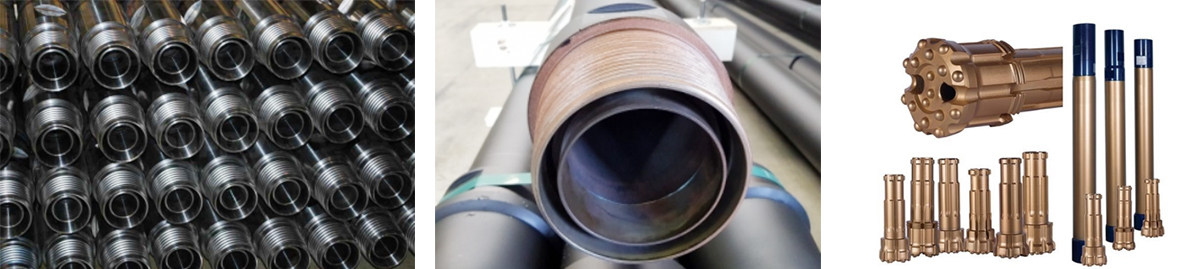

1. REVERSE CIRCULATION (RC TOOLS)

• AIIRC threads (MPD, CSR, CIP, Metzke, Remet, Reconn)

• Hex style large RC tools also available

• Interchanges and umbrella subs

• RC pipe

• RC discharge heads and Air Swivels

• RC Hammers

2. BITS

• Tricone, PDC, Claw Bits, and custom bit types

• Bits for any formation type

• Can be made with custom threads

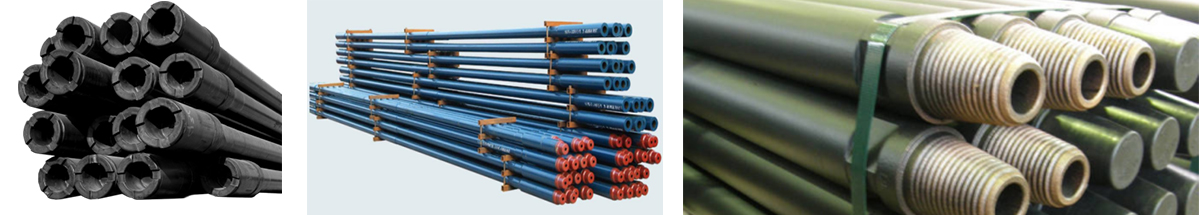

3. DRILL PIPE

• All API threads (REG, IF, FH, PAC), BECO, AWJ, NWJ, Rope threads. Modified Buttress, Barber threads, Kelly rod. Hex rod, RC threads. Sonic threads, and custom threads

• Any length and diameter

• Any wrench flats needed

• High alloy steel tool joints

4. ADAPTORS (FLOAT SUBS, CROSS OVERS, SAVER SUBS)

• All API threads (REG, IF, FH, PAC), BECO, AWJ, NWJ, Rope threads, Modified Buttress, Barber threads, Kelly rod, Hex rod, RC threads, Sonic threads, and custom threads

• Any length and diameter

• Any wrench flats needed

• Alloy, stainless, or non mag

5. CASING (SACRIFICIAL OR REUSABLE)

• All threads (STC, LTC, BTC, FJ, Rope threads, sonic threads, barber threads, modified buttress; • right hand or left, 1, 2 or 3 start)

• Any length

• Any grade

• Any diameter and wall thickness

Copyright ©Tianjin Grand Construction Machinery Technology Co., Ltd. All Rights Reserved. | Sitemap