Understanding the capabilities of surface testing equipment in oil and gas well drilling

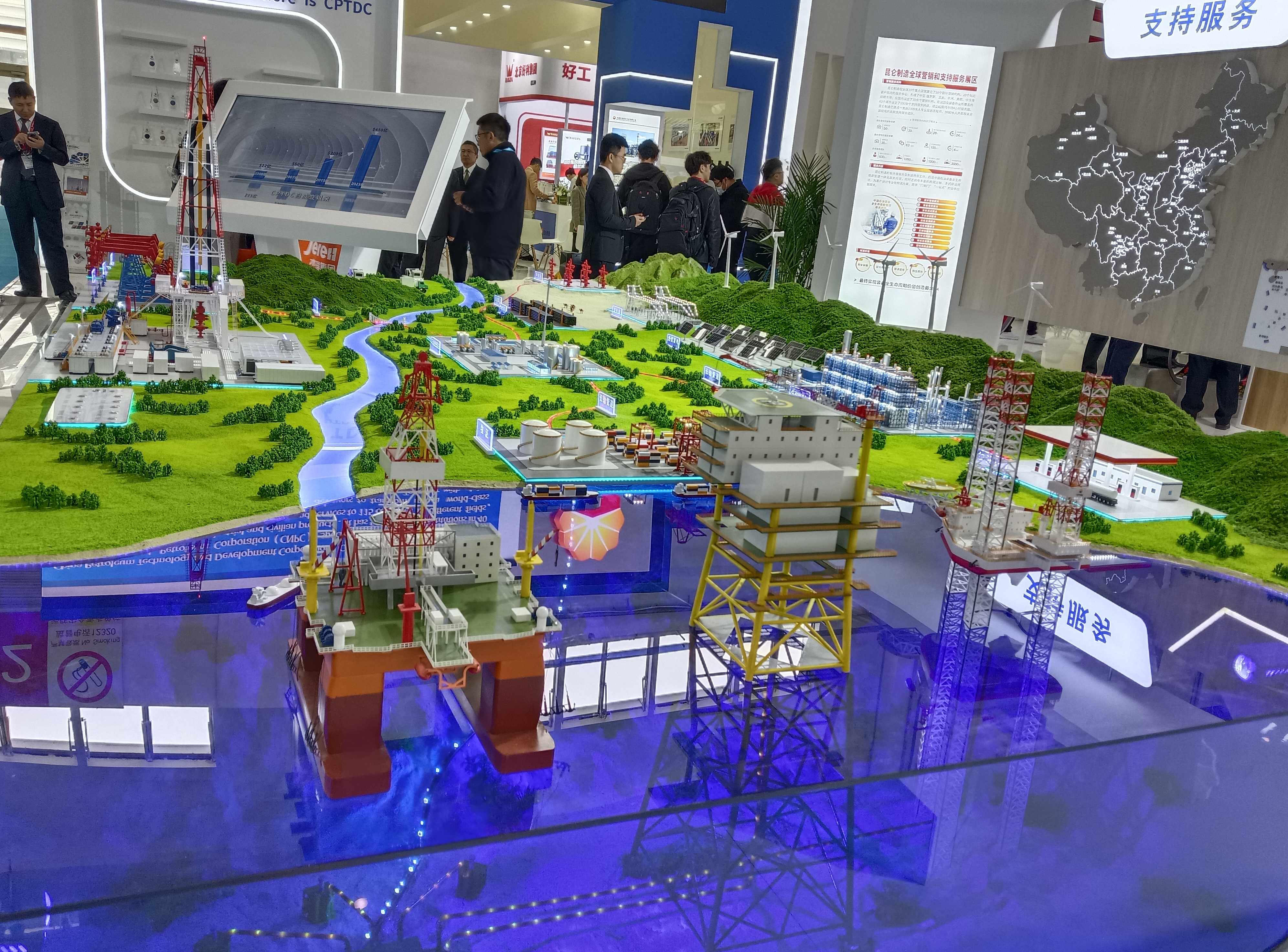

When it comes to oil and gas drilling, the use of surface testing equipment is critical to ensuring the efficiency and safety of the drilling process. This equipment plays a vital role in assessing well productivity and determining the quality of the oil and gas extracted. In this blog, we’ll take a closer look at the capabilities of surface testing equipment and how it works in oil and gas well drilling.

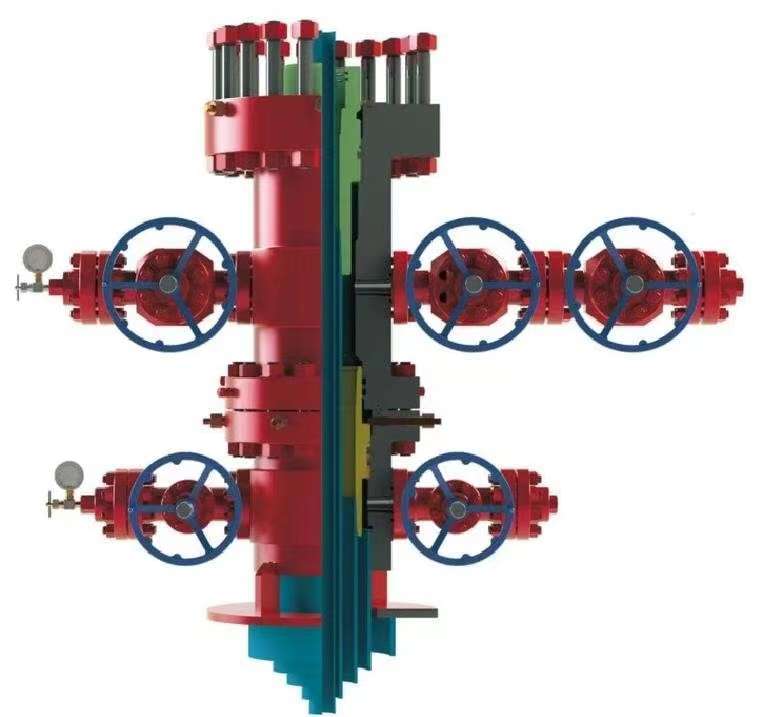

Surface testing equipment is designed to measure and analyze oil and gas flow from the wellhead to the surface. It consists of various components such as flow meters, pressure gauges, and separators, all of which work together to provide accurate data on the well's production capabilities. The equipment's primary function is to monitor and control the flow of fluids in the well, ensuring that the extraction process is efficient and safe.

One of the key components of surface testing equipment is the flow meter, which measures the rate of fluid flowing out of the well. This data is critical in determining a well's productivity and estimating the total amount of oil and gas that can be recovered. By accurately measuring flow, operators can make informed decisions about production optimization and resource management.

Pressure gauges are another critical component of surface testing equipment. These pressure gauges are used to monitor pressure levels in wells and surface equipment. By keeping a close eye on pressure, operators can ensure the drilling process is occurring within safe operating limits. Additionally, pressure data are critical for assessing reservoir characteristics and predicting their behavior during production.

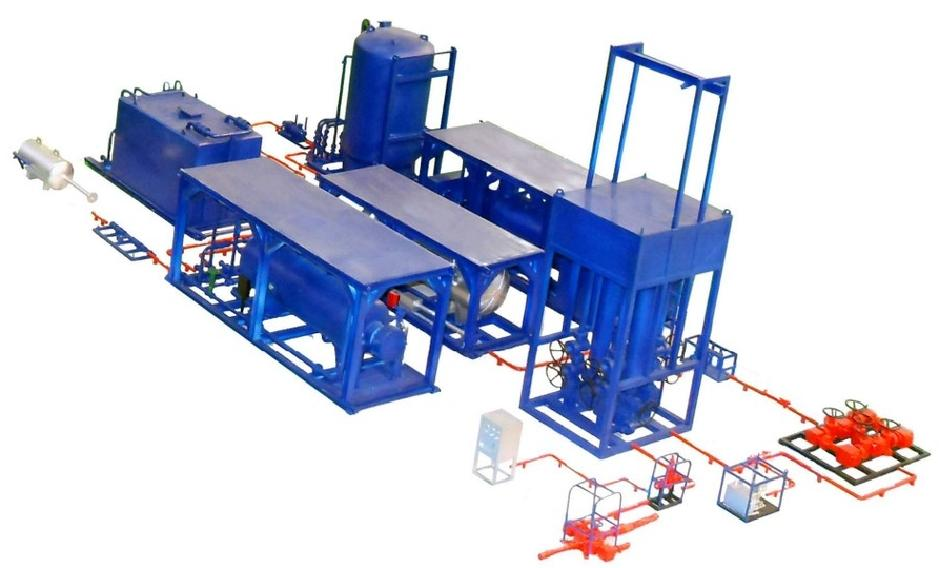

Separators are also an integral part of surface testing equipment. These devices are used to separate oil, gas and water extracted from wells. By separating these components, operators can accurately measure the individual volumes of oil, gas, and water to accurately calculate a well's production. This data is critical for determining the composition of the extraction fluid and optimizing the separation process.

So, how does surface testing equipment work in oil and gas well drilling? This equipment is usually installed at the wellhead and connected to the production line. As fluids flow from the well to the surface, they flow through various components of the surface test equipment where they are measured, monitored and separated. The data collected by the equipment is then transmitted to the control room where it is analyzed and used to make informed decisions about the production process.

In summary, surface testing equipment plays a vital role in efficiently and safely extracting oil and gas from wells. By measuring flow, monitoring pressure levels and separating extracted fluids, the device provides the necessary data to optimize production and ensure the well's productivity. Understanding the capabilities of surface test equipment is critical to successful oil and gas well drilling operations.