Understanding the functions of kill manifolds in well control systems

In the oil and gas industry, well control is critical to ensuring the safety and efficiency of drilling operations. The kill manifold is an important part of the well control system and plays a vital role in managing well pressure and preventing blowouts. Understanding how a kill manifold works is critical for anyone involved in drilling operations. In this blog, we will take an in-depth look at the functionality and operation of a kill manifold in a well control system.

The kill manifold is a key device used to control wellbore pressure in well control operations. It is usually installed between the blowout preventer (BOP) and the choke manifold. The primary function of a kill manifold is to provide a means of injecting heavy fluids, such as drilling mud or specialized kill fluids, into the wellbore to control well pressure and ultimately regain control of the well.

During drilling operations, unexpected pressure surges or influxes of formation fluids into the wellbore may occur, which, if not managed properly, may result in a blowout. In this case, the kill manifold comes into play. By diverting fluid flow from the wellbore to a kill manifold, heavy fluids can be pumped into the well to offset pressure and regain control.

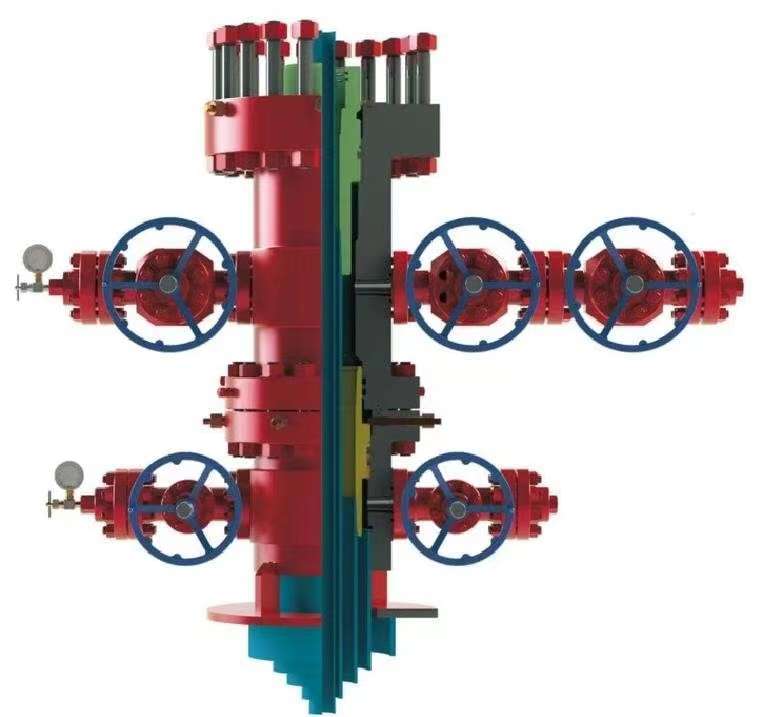

A kill manifold typically consists of a series of valves, chokes and pipes designed to handle high-pressure fluids. These valves are used to control the flow of fluids and isolate different parts of the manifold as needed. A choke is used to regulate the flow and pressure of fluid injected into a well. Pipes are designed to withstand high pressure conditions and ensure safe transfer of fluids.

Operation of the kill manifold requires a coordinated effort between the drilling crew and the well control team. When a pressure surge is detected, the blowout preventer closes to isolate the wellbore and the kill manifold is activated. The heavy fluid is then pumped into the kill manifold and into the wellbore to offset pressure surges. Adjusting the choke valve on the kill manifold controls the flow and pressure of the injected fluid, allowing the well control team to gradually regain control of the well.

In addition to controlling pressure kicks, kill manifolds are used for well control operations such as shut-in and kill wells. In the event of a blowout, kill manifolds play a key role in regaining control of the well and preventing further escalation.

In summary, the kill manifold is an important component of the well control system, providing a means of injecting heavy fluids into the wellbore to control pressure and prevent blowouts. Understanding how kill manifolds work and their role in well control operations is critical to ensuring the safety and success of drilling operations in the oil and gas industry.