Understanding the Functions of Three-Phase Separators in the Drilling Industry

In the drilling industry, efficient separation of oil, natural gas and water is critical to the success of drilling operations. This is where the three-phase separator plays an important role. Understanding how a three-phase separator works is critical to ensuring the drilling process runs smoothly and efficiently.

Three-phase separators are key pieces of equipment used in the oil and gas industry to separate fluids produced in wells into their respective components: oil, natural gas, and water. This separation process is critical to maximizing the production of valuable resources while minimizing environmental impact.

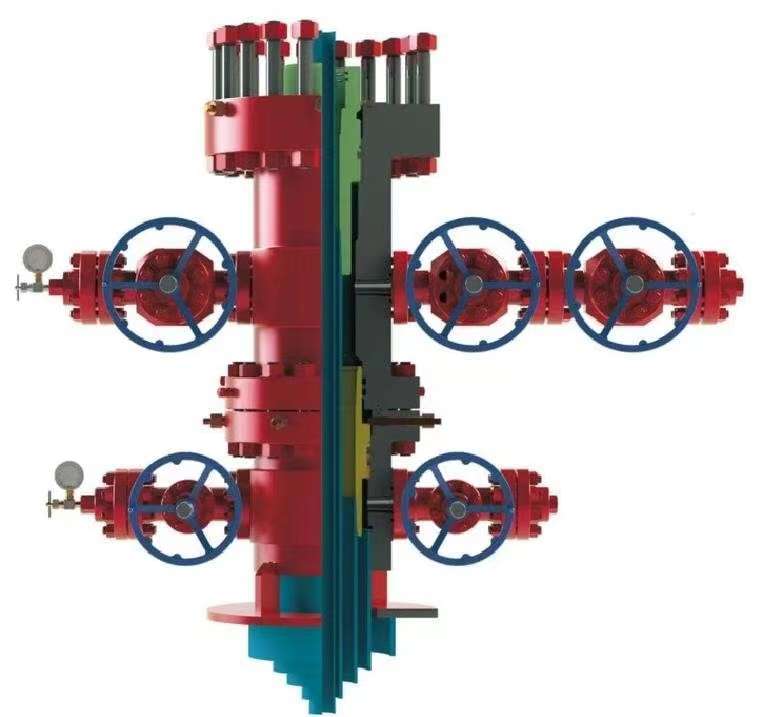

The operation of a three-phase separator involves several key steps. First, the fluid produced in the well is directed to a separator, where it undergoes a series of physical and mechanical processes to separate oil, gas, and water. Separators use differences in the density and phase behavior of fluids to achieve this separation.

The separation process begins with initial phase separation, where gas and liquid components separate. This is typically accomplished through the use of internal components such as baffles and mist eliminators, which help separate gases from the liquid stream. The separated gas is then directed out of the separator, while the liquid components continue the separation process.

Once the gas is removed, the next step is the separation of oil and water. This is accomplished by using gravity and the density difference between the two liquids. The separator is designed so that oil rises to the top, forming a distinct layer, while water settles at the bottom. Internal components such as weirs and skimmers help facilitate this separation process, ensuring effective separation of oil and water.

The separated oil and water are then directed to their respective outlets, where they can be further processed or treated as needed. Efficient separation of these components is critical to ensure the quality of the oil and water produced and to meet regulatory and environmental standards.

In addition to the physical separation process, the three-phase separator also integrates instrumentation and control systems to monitor and regulate the separation process. This includes the use of level sensors, pressure gauges and control valves to ensure the separator is operating within optimal parameters and directing separated components to the appropriate outlet.

Overall, the operation of three-phase separators in the drilling industry is critical for efficient separation of oil, gas, and water from produced fluids. By understanding how three-phase separators work, operators can ensure that the drilling process runs smoothly and valuable resources are successfully extracted from the surface.